Pneumatic Rotary Cutters: An Overview

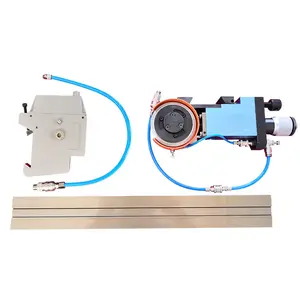

Pneumatic rotary cutters are essential tools in the paper production industry, designed to enhance efficiency in manufacturing processes such as toilet paper, napkins, and other paper products. These cutters are versatile and can be integrated into various production lines, catering to the needs of large-scale hotels, manufacturing plants, and paper processing industries.

Types and Applications

The range of pneumatic rotary cutters available varies in size and capability, making them suitable for different scales of production. From compact models ideal for small-scale operations to robust units capable of meeting the demands of high-volume production, these cutters are integral in the creation of paper goods, including serviettes and paper cups.

Features and Technical Specifications

A standard pneumatic rotary cutter is equipped with multiple units for embossing, slitting, folding, and counting. The embossing process can be accomplished with various patterns, utilizing steel-to-steel or steel-to-rubber configurations. The cutters are engineered to operate with either gear or chain driving systems, with many models boasting full automation and automatic oil lubrication for sustained performance.

Advanced models incorporate photoelectric technology to monitor operations, ensuring reliability and safety by alerting to paper shortages or operational issues. With weights starting at approximately 1,000kgs for smaller units and exceeding 3,000kgs for larger machines, these cutters are designed to accommodate different production needs, with capacities ranging from 70 pieces per minute to 3 tons per day.

Automation and Control

The pneumatic systems of these cutters are often managed via a PLC control panel, which streamlines the production process and allows for seamless automation. This level of control is crucial for maintaining consistent quality and optimizing the manufacturing workflow.

Materials and Construction

Constructed to endure the rigors of continuous operation, pneumatic rotary cutters are typically made from durable materials that promise longevity and consistent performance. The integration of automatic oil lubrication systems further ensures that the machines maintain their operational integrity over time.

Advantages of Using Pneumatic Rotary Cutters

The adoption of a pneumatic rotary cutter in paper production brings numerous advantages, including improved precision in cutting, increased production speed, and a reduction in manual labor. These cutters are designed to be user-friendly, with some models featuring touch screen interfaces for easy operation and adjustments.

Incorporating a pneumatic rotary cutter into your production line can significantly enhance operational efficiency. To explore the variety of options and find a cutter that aligns with your production requirements, visit Alibaba.com and connect with a network of experienced suppliers ready to assist with your paper processing needs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4