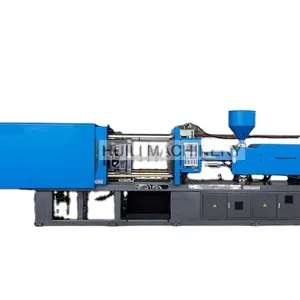

Introduction to Plastic Flower Pot Injection Machines

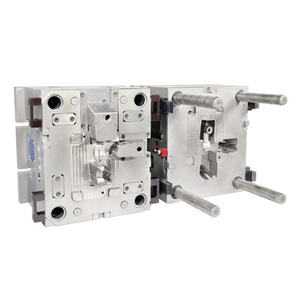

Plastic flower pot injection machines are specialized equipment used in the mass production of plastic flower pots. These machines utilize advanced injection molding technology to efficiently produce pots that are both functional and aesthetically pleasing. The process involves melting plastic granules and injecting them into a mold where they cool and solidify into the desired shape.

Types and Applications

The versatility of plastic flower pot injection machines allows them to cater to various sectors beyond horticulture. They are instrumental in creating products for consumer electronics, pharmaceuticals, food and beverage, and the automotive industry. The adaptability of these machines means they can be configured for a multitude of high-end applications, making them a valuable asset in diverse manufacturing environments.

Features and Technical Specifications

A plastic flower pot injection machine is designed with a special screw to enhance plasticizing shot weight and speed, ensuring efficient production. The clamping force of these machines can range significantly, equipped to handle the external forces of machining. With a focus on precision, these machines shape plastic granules into accurate dimensions, meeting the stringent requirements of the packaging industry for products like thin wall containers and various PVC pipe fittings.

Materials and Construction

The construction of a plastic flower pot injection machine involves robust materials that contribute to its longevity and consistent performance. The steel bush in the clamping unit is engineered to minimize wear resistance, which also reduces the need for lubrication oil, potentially lowering operational costs. This attention to material quality and design detail underscores the machine's reliability in producing flower pots and other plastic items.

Advantages of Using Advanced Molding Equipment

Investing in a plastic flower pot injection machine brings several advantages. The precision and speed of these machines lead to improved accuracy in applications, which is crucial for maintaining competitive edge in the market. Additionally, the durability of the equipment ensures a longer service life, providing more value over time. The single-cylinder system with a servo-valve is engineered for a responsive operation, aligning with industry standards for production efficacy.

Choosing the Right Machine for Your Needs

Selecting the appropriate plastic flower pot injection machine involves considering the specific requirements of your production line. Each machine offers a different clamping force and plasticizing capacity, tailored to various sizes of preforms and applications. It is essential to assess the exact clamping force and other technical specifications to ensure the machine meets your manufacturing needs without excess capacity or underperformance.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4