Introduction to BGA Mounting Solutions

Ball Grid Array (BGA) mounting is a pivotal process in the realm of electronic circuit board assembly. This technique involves attaching BGA packages onto PCBs (Printed Circuit Boards), which is essential for integrating complex semiconductor devices. The mounting BGA process requires precision and the right equipment to ensure reliable soldering and functionality of the electronic components.

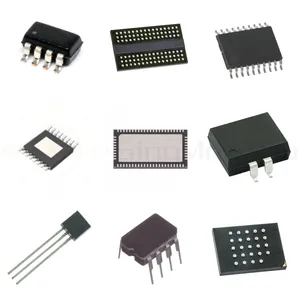

Types of BGA Mounting Equipment

The equipment for mounting BGA varies from manual stations for low-volume production to sophisticated automatic machines for high-throughput requirements. These systems cater to different BGA package sizes and complexities, ensuring there is a suitable solution for various assembly needs. The selection includes reflow ovens, which are crucial for creating solid solder joints, and inspection systems that verify the integrity of the connections post-mounting.

Applications and Features

BGA mounting technology is utilized across diverse industries, from consumer electronics to automotive manufacturing. The equipment designed for mounting BGA components is built to handle a range of materials, ensuring versatility for different project requirements. Features such as programmable profiles and temperature controls are integral to the process, allowing for adaptability and precision in soldering BGA packages.

Materials and Advantages

The materials used in BGA mounting equipment are selected for durability and thermal stability. This ensures that the machines can withstand the high temperatures required for soldering without compromising their integrity. The advantages of using BGA mounting include enhanced electrical performance and space-saving on the PCB, which is critical for modern, compact electronic devices.

Technological Integration

Modern BGA mounting systems incorporate advanced technologies that facilitate ease of use and increased efficiency. Features such as digital interfaces allow for user-friendly operation, while automatic vision systems enable precise alignment and placement of BGA packages. These technological advancements contribute to the reduction of manual labor and potential for human error.

Choosing the Right BGA Mounting Equipment

Selecting the appropriate mounting BGA equipment involves considering the specific requirements of your project, including the type of BGA packages and the volume of production. Equipment size also plays a role, with options ranging from compact, benchtop models to larger, floor-standing units. It is essential to assess the compatibility of the equipment with the intended BGA packages and the production environment to ensure optimal performance.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4