Popular in your industry

Top categories

About mixer plough

Introduction to Mixer Plough

Mixer plough, also known as a plough mixer or plow mixer, is a versatile industrial mixing machine widely used in various sectors such as food processing, pharmaceuticals, chemicals, and construction. It is designed to mix dry powders, granules, and fibrous materials with high efficiency and consistency. The unique design of the mixer plough ensures thorough mixing and blending of ingredients, making it an essential tool for manufacturing processes that require homogeneous mixtures.

Design Features of Plough Mixer

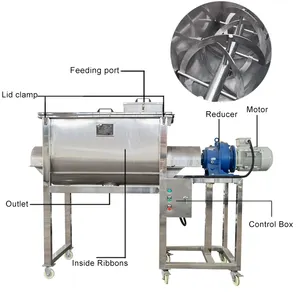

The plough mixer is characterized by its distinct mixing elements, commonly referred to as ploughs or plows, that rotate and sweep through the materials in a fluidized bed. This action creates a three-dimensional mixing effect, ensuring that all components are uniformly distributed. The ploughs are adjustable, allowing for customization of the mixing intensity and residence time, making the plough mixer suitable for a wide range of applications.

Technical Specifications of Plough Share Mixer

When considering a plough share mixer, it is essential to take into account key technical specifications such as the mixing capacity, motor power, rotational speed, and material of construction. Plough mixers are available in various sizes, ranging from laboratory-scale units to large industrial mixers capable of handling several tons of material per batch. The motor power typically ranges from 5 to 100 horsepower, depending on the size and application requirements.

Advantages of Plough Mixer Design

The plough mixer design offers several advantages, including efficient mixing of cohesive materials, gentle handling of fragile particles, and the ability to incorporate liquid additives during the mixing process. The design also allows for quick and thorough cleaning between batches, reducing cross-contamination and ensuring product quality. Additionally, the robust construction of plough mixers ensures durability and long-term reliability in demanding industrial environments.

Applications and Use Scenarios

The versatility of the mixer plough makes it suitable for a wide range of applications, including mixing dry powders for the food and pharmaceutical industries, blending abrasive materials in the chemical sector, and homogenizing granular products in the agricultural sector. Plough mixers are commonly used in the production of pharmaceutical formulations, pet food, fertilizers, and construction materials, highlighting their importance across diverse industries.

Choosing the Right Plough Mixer

When selecting a plough mixer for your specific application, consider factors such as the type of materials to be mixed, desired batch size, required mixing intensity, and cleaning and maintenance requirements. It is essential to choose a mixer that aligns with your production goals and quality standards to ensure optimal mixing performance and product consistency.

Maintenance and Care Tips

To maximize the lifespan and performance of your plough mixer, regular maintenance and care are essential. Clean the mixer thoroughly after each use to prevent product buildup and contamination. Inspect the mixing elements and drive components regularly for signs of wear and tear, and replace any worn parts promptly to avoid operational disruptions. Proper lubrication of moving parts and adherence to maintenance schedules will help ensure the long-term reliability of your plough mixer.