Popular in your industry

Related Searches:

Top categories

About lamination press machine

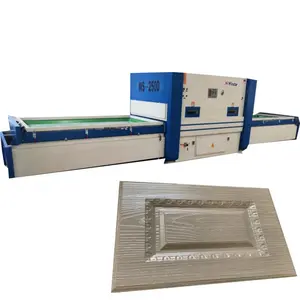

Introduction to Lamination Press Machine

A lamination press machine is a specialized industrial equipment used for laminating multiple layers of materials together by applying heat and pressure. It is widely used in various industries such as woodworking, automotive, aerospace, and electronics to create high-quality laminated products. The machine consists of a sturdy frame, hydraulic system, heating elements, and control panel to ensure precise operation.

Technical Specifications

When considering a lamination press machine, key technical specifications to look for include the maximum pressure capacity, temperature range, platen size, and overall dimensions. These machines typically have a pressure capacity ranging from 50 to 500 tons, a temperature range of 0 to 300 degrees Celsius, and platen sizes varying from 4 feet by 8 feet to 6 feet by 12 feet. The overall dimensions of the machine play a crucial role in determining the floor space required for installation.

Types of Lamination Press Machines

There are several types of lamination press machines available in the market to cater to different lamination needs. These include hot press machines, cold press machines, vacuum press machines, and multi-daylight press machines. Hot press machines are suitable for high-temperature lamination, while cold press machines are ideal for delicate materials. Vacuum press machines ensure uniform pressure distribution, and multi-daylight press machines offer high efficiency for large-scale production.

Features and Advantages

The lamination press machine is equipped with advanced features such as programmable logic controllers (PLCs) for precise temperature and pressure control, safety sensors to prevent accidents, and automatic opening and closing systems for efficiency. One of the main advantages of these machines is their ability to produce uniform laminates with high bonding strength, enhancing the overall quality of the end products.

Industrial Applications

Lamination press machines find extensive applications in industries such as furniture manufacturing, automotive interiors, printed circuit board (PCB) production, and composite materials manufacturing. In the furniture industry, these machines are used to laminate decorative veneers onto plywood or MDF boards, creating aesthetically pleasing surfaces. In the automotive sector, they are employed to laminate fabrics for car interiors, providing durability and aesthetics.

Choosing the Right Lamination Press Machine

When selecting a lamination press machine for your business, it is essential to consider factors such as production volume, material type, required pressure and temperature settings, and budget constraints. Additionally, opting for a machine from a reputable manufacturer with a proven track record of reliability and after-sales support is crucial to ensure smooth operations and minimal downtime.

Maintenance and Care

Proper maintenance of a lamination press machine is essential to prolong its lifespan and ensure consistent performance. Regular inspection of hydraulic systems, heating elements, and safety mechanisms is recommended to prevent unexpected breakdowns. Additionally, following the manufacturer's guidelines for cleaning, lubrication, and calibration will help maintain the machine in optimal working condition.