Exploring the Versatility of Iron Melting Pots

Iron melting pots, integral to metalworking industries, serve as the crucible for transforming raw metals into usable forms. These robust containers are designed to withstand extreme temperatures, making them suitable for a variety of metals beyond just iron, including aluminum, copper, and precious metals like gold and silver. The versatility of these pots is evident in their ability to handle different melting points, from the high thresholds required for cast iron melting to the more delicate needs of small cast iron melting pots for intricate work.

Types and Applications of Melting Pots

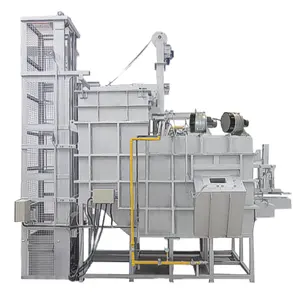

The range of iron melting pots extends from large-scale industrial models to smaller, specialized variants like the lodge melting pot. Larger pots are capable of processing up to 20 tons of metal, catering to extensive manufacturing processes. Conversely, items such as the antique cast iron melting pot reflect a history of metalwork, often sought after for both functional and decorative purposes. These pots are not only tools of trade but also bear cultural significance, echoing the legacy of metal crafting.

Features and Operational Insights

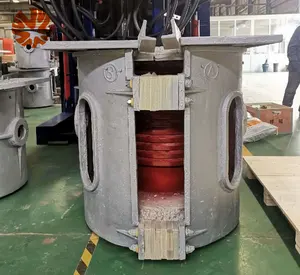

Operational efficiency is a hallmark of modern iron melting pots, with many utilizing electrical induction systems for heating. This method is complemented by hydraulic systems that facilitate the tilting of pots, allowing for precise control when pouring molten metal. The melting process can vary in speed, but typically falls within a 40 to 60-minute window, showcasing the efficiency of contemporary designs like the lodge cast iron melting pot with silicone brush, which combines functionality with additional features for user convenience.

Construction and Safety Aspects

Safety is paramount in the design of iron melting pots. Features such as insulated large capacitor banks ensure stable current flow, while built-in circuit breakers act as fail-safes against electrical faults. The construction materials of a cast iron smelting pot are chosen for their durability and heat resistance, ensuring a long service life and protection for operators. Additionally, water-cooling systems are standard in many pots, aiding in the rapid cooling of hot metals post-melting.

Advantages of Modern Melting Technology

The contemporary melting pot of iron is a testament to the advancements in melting technology. With the ability to reach temperatures between 1,750 to 2,100 degrees Celsius, these pots can efficiently melt a wide range of metals. The integration of PLC systems for operation streamlines the melting process, allowing for precise control and monitoring, which is particularly beneficial in settings where the cast iron lead melting pots are used for specialized tasks.

Choosing the Right Iron Melting Pot

Selecting the appropriate iron melting pot requires consideration of the specific metalworking needs. Whether the task calls for a vintage cast iron smelting pot for its unique characteristics or a more modern lodge cast iron melting pot for everyday use, the selection is vast. Each pot is designed with particular features to suit different melting requirements, ensuring that metalworkers can find the right tool for their craft.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4