Understanding Heat Resistant Liners

Heat resistant liners are essential components in various industrial and commercial settings, designed to withstand high temperatures and provide insulation. These liners come in multiple forms, each tailored to specific applications and environments. They are crafted from materials capable of sustaining intense heat without degrading, making them indispensable in operations where thermal management is critical.

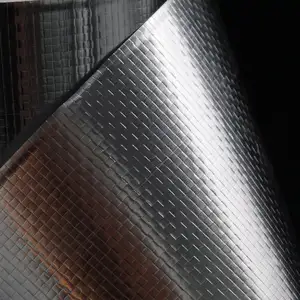

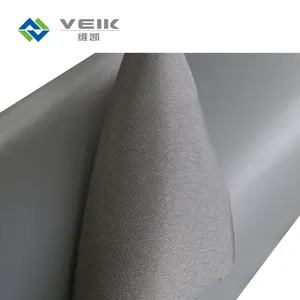

Types and Materials

The diversity of heat resistant liners is evident in their range of materials and construction. Options include aluminum foil for reflective insulation, fiberglass for robust thermal resistance, and polyethylene (PE) for versatile applications. Woven fabrics are also employed for their resilience and insulating capabilities. Each material offers unique benefits, ensuring that there is a liner suitable for every requirement.

Applications and Features

These liners are not limited to a single use but can be applied to metals, roofs, plastics, and fabrics, among others. The thermal insulation liners are engineered to maintain their integrity in extreme conditions, providing a reliable barrier against heat. Features such as waterproofing and additional protective traits like resistance to wear and tear are also integral to their design, enhancing their utility across various industries.

Advantages of Heat Resistant Liners

The advantages of using heat resistant liners are manifold. They contribute significantly to energy efficiency by reducing heat loss and offer protection to personnel and equipment in high-temperature environments. The liners' durability means they are a long-term solution for thermal management, and their eco-friendly properties ensure they align with sustainable practices.

Selection and Customization

Alibaba.com hosts a vast array of heat insulation liners, available in different sizes, colors, and shapes to meet specific industry needs. While customization is a key aspect of these products, it is essential to select the appropriate liner based on the operational demands it will face. The platform facilitates this selection by providing detailed information on the properties and potential applications of each liner.

Environmental Impact and Efficiency

In today's eco-conscious market, the role of insulation liners extends beyond just insulation. These products contribute to creating more energy-efficient systems and can also play a part in temperature regulation, aiding in the reduction of heating and cooling costs. Their contribution to environmental sustainability is as significant as their role in industrial and commercial efficacy.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4