Understanding High-performance Dyneema Fabric

High-performance Dyneema fabric, a specially engineered textile material, is recognized for its exceptional strength and lightweight nature. It is essentially a brand of ultra-high-molecular-weight polyethylene (UHMWPE or UHMW), known for its remarkable durability and robustness. This fabric serves not only the fashion and sports sectors but also extends its utility to diverse fields such as aerospace, military, and industrial safety.

The fundamental attributes of High-performance Dyneema fabric are rooted in its high tensile strength and low weight. Tensile strength denotes a material's ability to withstand tension without breaking. Notably, compared to conventional fabrics in various applications, High-performance Dyneema fabric stands out due to its extraordinary tensile strength, surpassing that of steel significantly on a weight-for-weight basis. Furthermore, it boasts exceptional abrasion resistance, rendering it ideal for demanding environments where longevity is pivotal.

The manufacturing process of High-performance Dyneema fabric involves gel spinning, where the material is extruded through a spinneret to form ultra-fine filaments. These filaments are then aligned and stretched to achieve the desired strength characteristics. The resultant fabric not only exhibits strength but also features a high melting point, along with resistance to diverse chemicals and solvents, enhancing safety and longevity in its applications.

Varieties of High-performance Dyneema Fabric

The market presents an extensive range of high-performance Dyneema fabrics, each tailored to specific applications based on their distinct properties.

-

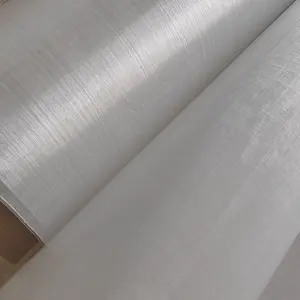

Unidirectional Dyneema Fabric: This fabric comprises Dyneema fibers aligned in a single direction to maximize strength along that axis. It is commonly employed in ballistic armor panels for its exceptional ballistic performance.

-

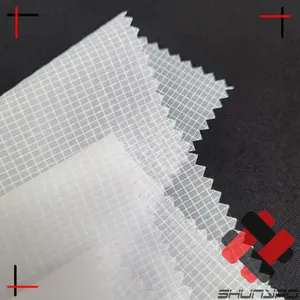

Woven Dyneema Fabric: Woven with Dyneema fibers in both directions, this fabric offers a balance of strength and flexibility. It is frequently utilized in applications like high-performance sports equipment and advanced protective wearables.

-

Hybrid Dyneema Fabric: By blending Dyneema with materials like carbon fiber or Kevlar, hybrid fabrics combine properties suitable for specific uses, such as in aerospace or advanced ballistic armor.

-

Ultra-High Molecular Weight (UHMW) Dyneema Fabric: This variant, a recent development, emphasizes enhanced durability and abrasion resistance. It has gained substantial traction in cut-resistant gloves and as backing for bullet-proof inserts.

Selecting High-performance Dyneema Fabric

Choosing the appropriate high-performance Dyneema fabric necessitates a thoughtful evaluation of the specific requirements of the intended application. Businesses should consider factors such as required strength, weight, flexibility, and resistance to environmental conditions when selecting a fabric for protective gear or high-strength applications.

For applications prioritizing flexibility, like climbing ropes or industrial slings, a woven fabric offering high tensile strength and some elasticity may be most suitable. Conversely, for rigid applications such as bullet-proof vests or structural reinforcements, a compacted fabric with high modulus would be preferable.

Environmental factors, including UV resistance for outdoor use and corrosion resistance for marine environments, are crucial considerations. Additionally, the fabric's performance in varying temperatures is essential, as some fabrics may lose strength at high temperatures or become brittle in cold climates.

Moreover, comprehending Dyneema's molecular structure and its response to external forces can aid in tailoring the fabric choice to meet the application's specific demands.

Exploring High-performance Dyneema Fabric on Alibaba.com

For businesses seeking high-performance Dyneema fabrics, Alibaba.com offers a diverse selection catering to a wide array of applications. As a longstanding global marketplace connecting buyers with suppliers, Alibaba.com has established itself as a dependable platform where businesses can discover specialized fabrics meeting their precise needs. From advanced protective gear to lightweight apparel materials, Alibaba.com features an extensive network of suppliers offering products spanning various industries.

Alibaba.com provides a reliable sourcing avenue for Dyneema fabrics, supported by features like Trade Assurance, ensuring transaction protection until delivery completion. With tools facilitating communication in multiple languages and mobile-friendly purchasing options, Alibaba.com streamlines global fabric sourcing to align with diverse business requirements.

By furnishing comprehensive product details, including color choices, application insights, available processing services, and order quantities, Alibaba.com empowers businesses to make informed decisions when selecting the ideal fabric for their intended purposes. This commitment to enhancing international trade experiences positions Alibaba.com as a comprehensive solution for businesses in search of top-tier high-performance materials like Dyneema.

Frequently Asked Questions about High-performance Dyneema Fabric

Primary Applications of High-performance Dyneema Fabric

High-performance Dyneema fabric is predominantly utilized in applications necessitating high tensile strength, lightweight properties, and resistance to extreme forces. Its usage spans across industries such as defense, aerospace, maritime, medical, and manufacturing of personal protective equipment.

Comparative Strength of High-performance Dyneema Fabric

High-performance Dyneema fabric significantly surpasses traditional textiles in strength, with a tensile strength that can be up to 15 times higher than steel of equivalent weight. Its high resistance to cuts, abrasions, and chemicals positions it as an ideal choice for protective gear and heavy-duty applications.

Customization Potential of High-performance Dyneema Fabric

Indeed, high-performance Dyneema fabric can be customized concerning weight, thickness, weave type, color, and additional protective attributes. Suppliers may extend customization services to meet diverse application requirements.

Considerations for Environmental Exposure with High-performance Dyneema Fabric

When selecting high-performance Dyneema fabric for environmental exposure, factors like UV exposure, temperature fluctuations, and moisture levels should be taken into account. Application of protective coatings or treatments can enhance its resilience to varying environmental conditions.

Availability of Color Options for High-performance Dyneema Fabric

High-performance Dyneema fabric is offered in various colors, including white, black, yellow, and custom hues. The color selection may be influenced by the intended use and visibility needs.

Assessing Suitability of High-performance Dyneema Fabric for Specific Applications

To ascertain the suitability of high-performance Dyneema fabric for a particular application, evaluate its specifications in relation to environmental conditions, required strength, flexibility, and any additional protective attributes needed, such as cut resistance or flame retardancy.

Breathability of High-performance Dyneema Fabric

Some high-performance Dyneema fabrics are engineered to offer enhanced breathability while retaining their strength, often favored in applications where wearer comfort and protection are equally paramount.

Cost Considerations in Selecting High-performance Dyneema Fabric

Although high-performance Dyneema fabric may entail a higher initial cost compared to traditional textiles, its durability and prolonged service life generally offset the higher price over time.

Utilization of High-performance Dyneema Fabric in High-temperature Environments

Certain variants of high-performance Dyneema fabric are designed to endure exposure to high temperatures. It is imperative to opt for a fabric explicitly rated for such conditions.

Certifications Indicative of High-performance Dyneema Fabric Quality

Certifications like ISO standards or industry-specific safety certifications serve as indicators of quality assurance. It is advisable to verify with suppliers for certifications pertinent to your industry.

Application of Finishes on High-performance Dyneema Fabric

Common finishes like PU (polyurethane), PTFE (polytetrafluoroethylene), and PA (Nylon) are typically applied to high-performance Dyneema fabrics to enhance properties such as water repellency, stain resistance, and durability.

Determining Optimal Weight of High-performance Dyneema Fabric for Projects

The required weight of high-performance Dyneema fabric depends on the specific application. Lighter weights are suitable for weight-sensitive applications like aerospace or marine environments, while heavier weights are preferred for applications necessitating increased strength.

Possibility of Blending High-performance Dyneema Fabric with Other Materials

Absolutely, high-performance Dyneema fabric can be blended with materials like carbon fiber or glass fiber to enhance specific properties such as stiffness or conductivity.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4