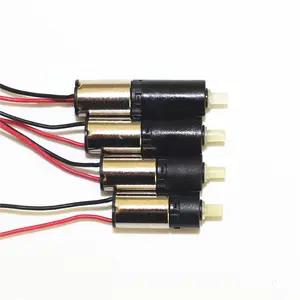

Understanding D Shape Motor Shafts

D shape motor shafts are integral components in various mechanical systems, providing a unique profile that ensures secure coupling in motor-driven applications. These shafts are designed to deliver precision and durability, catering to a wide range of industrial needs.

Types and Materials

The selection of d shape motor shafts encompasses various materials, each offering distinct characteristics. Steel shafts are known for their robustness and longevity, making them suitable for applications requiring high strength and control. Graphite shafts, on the other hand, are significantly lighter, which can enhance the operational efficiency of equipment. For those seeking the benefits of both, multi-material shafts combine steel and graphite to offer a balanced performance.

Flexibility and Performance

Flexibility is a critical attribute of d shape motor shafts, directly influencing the performance of the machinery they are part of. The flex range of these shafts caters to different operational speeds and styles. Shafts with less flex are optimal for high-speed applications, while those with greater flex are better suited for slower, more controlled operations. For novice users, a shaft with increased flexibility is often recommended to accommodate a learning curve.

Torque Specifications

Torque is another pivotal specification in d shape motor shafts, with measurements in degrees reflecting the shaft's resistance to twisting forces. Graphite shafts typically exhibit higher torque levels, providing a softer feel, whereas steel shafts have lower torque, indicative of a firmer response during use. The torque rating not only affects the tactile feedback but also plays a role in the precision and stability of the equipment.

Applications and Suitability

The application of d shape motor shafts is extensive, ranging from industrial machinery to precision instruments. Their design is particularly advantageous for settings where secure motor-to-shaft connections are paramount. The choice of shaft is contingent upon the user's specific requirements, with various flexibilities and torques to match different operational demands and user experiences.

Choosing the Right Shaft

Selecting the appropriate d shape motor shaft is essential for optimal performance and longevity of the equipment. Factors such as material composition, flexibility, and torque should be carefully considered in relation to the intended application. While the choice is ultimately dependent on the user's needs, understanding these key characteristics can guide in making an informed decision.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4