Popular in your industry

Related Searches:

Top categories

About custom perforated metal cage

Exploring the Versatility of Custom Perforated Metal Cages

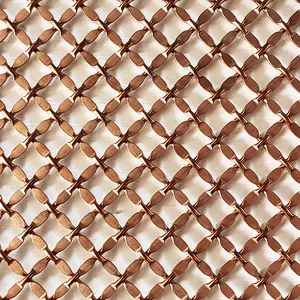

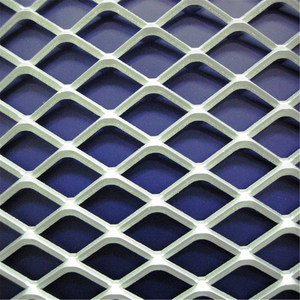

Perforated metal, a material characterized by its pattern of holes, slots, or decorative shapes, is utilized in the fabrication of custom perforated metal cages. These structures harness the strength and durability of metal while offering a unique combination of functionality and aesthetics. Catering to a diverse range of applications, these cages serve industries from architecture to agriculture, showcasing their adaptability and efficiency.

Types and Materials

The construction of perforated metal enclosures involves various metals, each selected for its specific properties. Stainless steel, known for its corrosion resistance, is a prevalent choice, offering longevity and structural integrity. Other materials include aluminum, which provides a lightweight yet robust alternative, and mild steel, which is often favored for its cost-effectiveness and strength.

Applications and Features

Perforated metal screens are integral to these cages, providing ventilation and visibility while maintaining security. The applications are extensive, ranging from protective barriers in machinery to aesthetic elements in architectural designs. Features such as weather resistance and environmental friendliness make these cages a practical option for outdoor and indoor settings alike.

Design and Customization

Design flexibility is a hallmark of perforated metal panels. Customization allows for a variety of shapes and sizes, tailored to specific needs. The perforation patterns can be as intricate or as simple as required, influencing not only the appearance but also the functionality, such as light diffusion or sound attenuation.

Advantages of Perforated Metal Cages

The advantages of using metal mesh cages are numerous. Their open yet secure structure ensures protection without sacrificing airflow, an essential feature for many industrial processes. Additionally, the ease of maintenance and the ability to withstand harsh environments make them a practical choice for long-term use.

Environmental Impact and Sustainability

Environmental considerations are increasingly important in material selection. Perforated metal fabrications align with sustainable practices, often being recyclable and having a lower environmental footprint compared to solid materials. This aspect is crucial for businesses aiming to reduce their ecological impact while maintaining high standards of operation.