Discover the Versatility of Double-Sided Coating Machines

Double-sided coating machines are integral components in modern manufacturing, offering a dual-sided application that enhances productivity and efficiency. These machines are designed to cater to a variety of materials, ensuring a consistent coating process on both sides simultaneously. This introduction delves into the capabilities and applications of coating machine double sided technology, a pivotal innovation for industries requiring precision and uniformity in coatings.

Types and Applications of Double-Sided Coating Equipment

The realm of coating machine double sided encompasses a range of models, from simple powder coaters to sophisticated hot melt coaters. These machines are adept at handling diverse materials, including metals, plastics, and textiles. Industries such as automotive, furniture, and construction benefit from the dual-sided coating for products like aluminum profiles, cabinet surfaces, and flooring materials. The adaptability of these machines allows for their use in coating small components like alloy wheels to larger items such as industrial pipes.

Features and Operational Excellence

A coating machine double sided is engineered for performance, boasting features that promote efficiency. With systems designed for quick color changes, the operation remains clean, minimizing dust and spillage. The user-friendly interface of these machines simplifies the coating process, with pre-set programs that facilitate ease of use for operators of varying skill levels. Additionally, the auto trimming system and customizable settings cater to specific coating requirements, enhancing the versatility of the equipment.

Material Compatibility and Environmental Considerations

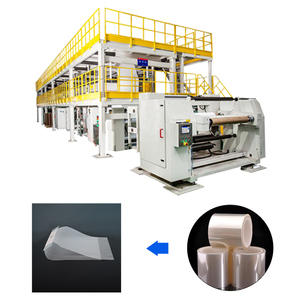

Compatibility with a wide array of materials is a hallmark of the coating machine double sided. Whether dealing with soft films for lamination or robust metallic surfaces, these machines ensure consistent application. Environmental considerations are also at the forefront, with features that support eco-friendly operations. This includes systems that aim to reduce overspray and promote a high powder recovery rate, contributing to sustainable manufacturing practices.

Advantages of Using Double-Sided Coating Technology

The advantages of utilizing a coating machine double sided are manifold. These machines offer a balance of durability and operational ease, with a focus on producing fade-resistant and uniformly adherent coatings. The dual-sided application streamlines the coating process, effectively doubling the production capacity without compromising on finish quality. Furthermore, the cost-effectiveness of these machines is evident in their high powder recovery rates, which contribute to reduced material waste and operational costs.

Enhance Your Manufacturing with Double-Sided Coating Solutions

In conclusion, the coating machine double sided stands as a testament to innovation in the coating industry. With its broad application spectrum, ease of operation, and commitment to environmental sustainability, it represents a smart investment for businesses looking to enhance their coating processes. Explore the diverse options available and integrate this technology to elevate the quality and efficiency of your production line.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4