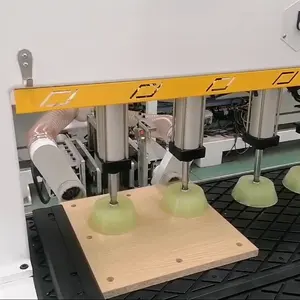

Introduction to CNC Multi Spindle Drilling Machines

CNC multi spindle drilling machines are integral components in modern manufacturing, designed to create precise holes in various materials. These machines utilize computer numerical control (CNC) to operate multiple spindles simultaneously, enhancing productivity and precision in drilling tasks.

Types and Applications

The versatility of multi spindle CNC drilling machines allows for their application across diverse industries. From woodworking to metalworking, these machines facilitate the creation of both cylindrical and tapered holes. The adaptability of CNC multi spindle drilling machines extends to various materials, making them suitable for a wide range of professional environments.

Operational Features

CNC multi spindle drilling machines are distinguished by their operational modes. Horizontal models work with spindles parallel to the worktable, ideal for lateral drilling operations. In contrast, vertical machines require the workpiece to be clamped before engaging the overhead spindle for vertical drilling. Line boring variants operate with a bar supported at both ends, ensuring stability and precision for extensive drilling requirements.

Technical Advantages

The efficiency of multi spindle cnc drilling machines is one of their most significant advantages. They expedite production processes, achieving more in less time compared to manual drilling. Additionally, these machines are engineered to operate without producing excessive noise or unpleasant odors, ensuring a more comfortable work environment.

Machine Construction and Materials

Constructed with durability in mind, CNC multi spindle drilling machines are made from robust materials that withstand rigorous use. The design of these machines focuses on longevity and maintaining precision over time, ensuring that they remain a valuable asset for any operation.

Choosing the Right Machine

Selecting the appropriate multi spindle CNC drilling machine involves considering the specific requirements of the task at hand. With a range of machines available, it is possible to find one that aligns with the desired hole shapes, sizes, and depths, ensuring efficient and effective drilling performance.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4