Introduction to CNC Knife Cutters

The surge in textile and apparel production necessitates advanced solutions to keep pace with market demands. Central to these solutions is the CNC knife cutter, a pivotal technology that streamlines the manufacturing process. CNC knife cutters are integral in transforming raw materials into finished products with efficiency and precision.

Types and Applications

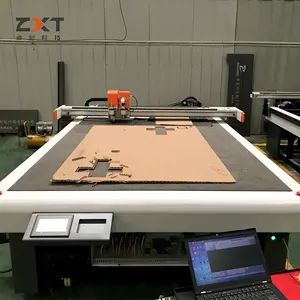

CNC knife cutting technology has evolved to include various models, each suited to specific industry needs. From automated fabric cutting machines to more specialized industrial cutting equipment, these tools are designed to handle different materials and production scales. Their applications span across textile production, garment manufacturing, and the creation of soft furnishings, demonstrating their versatility within the sector.

Technical Features

Modern CNC fabric cutting machines boast features that enhance productivity and accuracy. Precision cutting is a hallmark of these machines, ensuring minimal material waste and consistent quality. The integration of advanced software allows for intricate patterns and designs to be executed with exactness, a testament to the technological advancements in textile cutting solutions.

Material Handling and Efficiency

The materials used in the construction of CNC textile cutters are chosen for durability and performance. This ensures that the machines can withstand the rigors of high-volume production environments. Efficiency is also a key benefit, as these cutters reduce the labor intensity traditionally associated with textile manufacturing, leading to cost savings and enhanced safety for workers.

Advantages of CNC Knife Cutting Technology

The adoption of CNC cutting equipment in the textile industry brings multiple advantages. These machines facilitate rapid production without compromising on the quality of the cut or the final product. They also contribute to a safer working environment by automating processes that were once manual, reducing the risk of injury and improving overall workplace conditions.

Exploring CNC Knife Cutter Options

For businesses looking to procure CNC knife cutting machines, a diverse array of options is available. Whether the need is for upgrading existing machinery or expanding production capabilities, the selection of CNC knife cutters on Alibaba.com caters to a wide range of industry requirements. With a focus on connecting buyers with reputable suppliers, the platform is an essential resource for sourcing fabric processing equipment.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4