Popular in your industry

Related Searches:

Top categories

About calendering machines

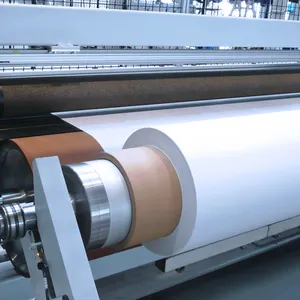

Introduction to Calendering Machines

Calendering machines are essential equipment in the textile and printing industries, designed to process various materials through heat and pressure. These machines are pivotal in finishing fabrics and imprinting designs on a multitude of flat and non-flat items. With a diverse range of applications, calendering machines cater to businesses looking to enhance their product offerings with precision and efficiency.

Types and Applications

The versatility of calendar machinery extends to printing on bags, hoodies, t-shirts, and more, while specialized models handle non-flat items like mugs and caps. From calendar press machines to calendar rimming machines, each variant serves a specific function in the production line, ensuring that businesses can select a machine that aligns with their operational needs.

Features and Specifications

Calendering machines come in various sizes, with some models being portable and lightweight, while others are more substantial, industrial units. The printing surface of these machines typically starts at 38 x 38 cm, accommodating a range of product sizes. They operate within a power consumption range of 600 to 2,000 watts and can reach temperatures up to 250 degrees Celsius. Additionally, most machines are equipped with a timer that can be set up to 999 seconds, and feature touch-sensitive LCD screens for precise control over temperature and timing.

Materials and Design

The heat plates of calendering machines are generally made from aluminum and coated with a non-stick material to ensure even heat distribution and prevent damage to the merchandise. Underneath the heat plate lies a heat-resistant rubber pad, which provides a stable base for clothing and other materials during the printing process. The design of these machines varies, with some having a heat plate that moves vertically, while others have a lateral movement, catering to different operational preferences.

Advantages of Modern Calendering Technology

Modern calendering machines offer semi-automatic operation, requiring manual adjustment of pressure and movement of the heat plate. This semi-automatic nature allows for greater control during the printing process, ensuring optimal results. The use of advanced materials like non-stick coatings and heat-resistant rubber enhances the functionality and durability of the machines. Whether it's a 3 roll calender machine or a 4 roll calender machine, businesses can benefit from the tailored configurations that these machines offer.

Choosing the Right Calendering Machine

Selecting the appropriate calendering machine for paper, textiles, or other materials requires careful consideration of the machine's capabilities and the specific needs of your business. Platforms like Alibaba.com host a wide array of calendering machines, from pvc calender machines to textile calender machines, without advocating for any particular brand or price point. This ensures that businesses can explore a comprehensive selection to find the machine that best fits their production requirements.