Braze Welding Machine: An Overview

Braze welding machines are specialized tools designed for joining metals by melting and flowing a filler metal into the joint, the filler metal having a lower melting point than the adjoining metal. Unlike the traditional welding process, braze welding allows for the joining of dissimilar metals and is ideal for tasks where precision and the integrity of the base metals are paramount.

Types and Applications

The versatility of braze welding machines is evident in their various types and applications. From mig brazing welders that offer the convenience of MIG welding with the added benefits of brazing, to water cooled induction welding brazing machines that are perfect for high-precision work requiring controlled temperatures, the range is extensive. These machines are utilized across industries, from intricate jewelry design to robust construction projects, showcasing their adaptability to both fine work and heavy-duty tasks.

Features and Materials

A braze welding machine can handle a plethora of materials, including copper, brass, aluminum, and steel. The machines come equipped with features that cater to different brazing methods such as arc, gas, and resistance brazing. For instance, mig brazing machines combine the efficiency of MIG welding with the gentleness of brazing, making them suitable for tasks that require a delicate touch.

Advantages of Braze Welding

The primary advantage of using a braze welding machine lies in its ability to join dissimilar materials without compromising their original properties. This process results in strong, leak-proof joints and is often preferred for its aesthetic finish. Additionally, the use of a brazing with mig welder can significantly reduce heat distortion, allowing for greater control and precision in the welding process.

Choosing the Right Machine

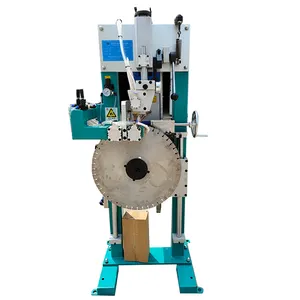

Selecting the right braze welding machine involves considering the specific requirements of the task at hand. For professionals looking for equipment that minimizes user fatigue and exposure to bright lights and sparks, an automatic braze welding machine with push-button operation and digital interfaces may be the ideal choice. These machines streamline the welding process and are designed to reduce downtime, enhancing productivity.

Conclusion

In conclusion, whether you require a portable unit for small-scale projects or a more complex setup for industrial applications, the comprehensive collection of braze welding machines on Alibaba.com caters to a wide spectrum of welding needs. By connecting buyers with a global supply base, the platform facilitates the sourcing of equipment that aligns with the diverse requirements of clients worldwide.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4