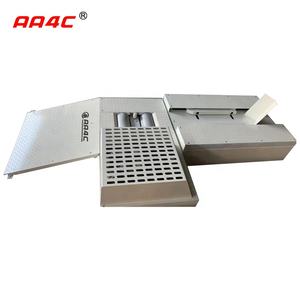

AA4C Auto Chassis Dynamometer Vehicle Sideslip Tester Vehicle Suspension Performance Tester ROLLER BRAKE TESTER

Wireless Auto Physical Chassis Dynamometer Force Measuring Instruments Tension Digital Force Gauge Load Cell Indicator

A braking dynamometer is an essential instrument in the realm of automotive testing, designed to measure the force exerted by a rotating system. By simulating various load conditions, these devices are crucial for assessing performance, endurance, and compliance with safety standards. This category encompasses a variety of models, each tailored to specific testing scenarios.

The versatility of braking dynamometers is evident in their types, such as the water brake, eddy current, and prony dyno. Each type serves a unique purpose, from high-power applications to more delicate testing environments. They are widely used in automotive development, repair shops, and even in educational settings for research and training purposes.

Braking dynamometers are engineered with precision, utilizing durable materials capable of withstanding the stress of repeated testing cycles. Features may include advanced control systems for accurate load simulation, robust data acquisition capabilities, and compatibility with various vehicles and machinery.

Employing a braking dynamometer in testing routines offers numerous advantages, such as precise control over test conditions and direct measurement of torque and power output. This leads to enhanced diagnostic capabilities, allowing for the fine-tuning of engine and powertrain systems.

When selecting a braking dynamometer, it is important to consider the specific requirements of the intended application, such as maximum torque, power capacity, and the type of dynamometer that best suits the testing environment. Additionally, factors like ease of integration with existing systems and data analysis software should be taken into account.

For comprehensive testing solutions, one might explore additional equipment such as vector network analyzers and circuit breaker testers. While not directly related to dynamometers, these tools complement the diagnostic process, ensuring all-around efficiency and reliability in testing and troubleshooting.