Popular in your industry

Related Searches:

Top categories

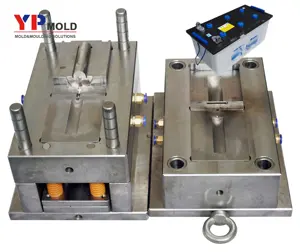

About battery terminal mold

Exploring Automotive Battery Terminal Molding

Automotive battery terminal molding is a precision-driven process that encapsulates battery terminals, safeguarding and stabilizing the electrical connections within a vehicle's battery apparatus. These pivotal components forge the connection between the battery and the vehicle's electrical circuitry, supplying essential power for ignition, lighting, and electronic devices. The molding technique furnishes a protective and visually appealing shell for these terminals, ensuring resilience against the rigors of the automotive milieu while presenting a refined appearance.

Geared towards manufacturers and enterprises engaged in automotive battery production or upkeep, this process is integral to a diverse array of vehicles, spanning from compact automobiles to hefty commercial trucks, and is a vital link in the automotive sector's supply chain. The ethos of automotive battery terminal molding hinges on meticulousness and a keen eye for detail, yielding a tailor-made casing that not only bolsters safety but also augments the battery's durability and efficacy.

In the course of molding, a precision-engineered tool or die shapes a thermoplastic compound around the battery terminal. This secures the connection and insulates the terminals from potential electrical mishaps, such as short circuits. The outcome is a robust and dependable battery terminal capable of withstanding vehicular vibrations and extreme temperature fluctuations. Moreover, the protective casings from these molds stave off corrosion, thereby extending the battery's service life.

Varieties of Automotive Battery Terminal Molding

Automotive battery terminal molding comes in several variants, each tailored to specific roles within the automotive realm. For example:

-

Standard Lead-acid Battery Terminal Molding: The predominant type for conventional lead-acid batteries, often characterized by a simple, flat or hexagonal design for straightforward attachment to the battery's poles. These are commonly installed in passenger vehicles and smaller commercial transports.

-

Heavy Duty Battery Terminal Molding: Crafted for larger conveyances such as trucks and buses, these molds boast a sturdy build to manage the increased electrical demands and sizable battery configurations typical of such vehicles. They frequently incorporate thicker steel plating and are designed for enduring performance under diverse conditions.

-

Hybrid and Electric Vehicle Battery Terminal Molding: Customized for the high-capacity batteries in electric and hybrid vehicles, these molds must accommodate more substantial terminals and complex designs, all while upholding stringent safety and dependability standards.

-

Lithium-Ion Battery Terminal Molding: With the rising adoption of lithium-ion batteries in the automotive industry, thanks to their superior energy density, the associated molds must adhere to exacting safety protocols due to the batteries' volatile characteristics.

Selecting the Right Automotive Battery Terminal Molding

Choosing a suitable automotive battery terminal molding process demands careful deliberation of various elements:

-

Material Compatibility: Verify that the molding technique is congruent with the materials comprising your battery terminals. For instance, hot runner systems are the preferred choice for molding materials like PPS (polyphenylene sulfide) that withstand high temperatures.

-

Production Volume: Account for the volume of terminals you intend to produce. Large-scale manufacturing might justify the investment in a costlier hot runner system, which delivers greater efficiency and shorter cycle times.

-

Complexity of Design: Evaluate the intricacy of your terminal design. Die casting might be the optimal approach for complex shapes, given its precision in molding highly detailed components.

-

Customization Requirements: If your project necessitates bespoke molds, seek suppliers that offer adaptable services capable of accommodating distinctive shapes or features particular to your specifications.

Discovering Automotive Battery Terminal Molding on Alibaba.com

Alibaba.com emerges as a comprehensive marketplace for businesses to source an extensive selection of automotive battery terminal molds for various applications. With a legacy spanning over two decades in bridging global suppliers with international buyers, Alibaba.com provides an unmatched platform for procuring premium molds that meet specific requirements without sacrificing diversity or customization possibilities.

The platform's intuitive interface enables buyers to swiftly navigate through options such as color, runner type, shaping mode, material, and features, ensuring a streamlined search for the ideal product. Furthermore, with safeguards like Trade Assurance offering payment protection until the fulfillment of delivery, businesses can transact with confidence on Alibaba.com.

Alibaba.com's dedication to smooth international commerce is reflected in its mobile optimization and multilingual communication tools, serving buyers globally. Regardless of business size, Alibaba.com presents solutions to address your battery terminal molding needs with precision and dependability.

Frequently Asked Questions on Automotive Battery Terminal Molding

What materials are typically employed in automotive battery terminal molding?

Commonly, automotive battery terminal molds are crafted from materials such as copper, brass, or stainless steel, prized for their superior electrical conductivity and robustness.

How is the correct size for a battery terminal mold determined?

The dimensions of a battery terminal mold must align with the specifications of the intended battery, information that is usually accessible from the manufacturer's data. Precise measurement of the terminal dimensions is imperative for an accurate fit.

Is it possible to customize automotive battery terminal molds?

Indeed, numerous suppliers on Alibaba.com provide customization services for automotive battery terminal molds to meet specific design criteria and configurations.

Are automotive battery terminal molds reusable?

Designed for durability and reusability, automotive battery terminal molds facilitate high-precision manufacturing and efficient production workflows.

What distinguishes hot runner from cold runner automotive battery terminal molds?

Hot runner molds are engineered to maintain a uniform temperature for the molten plastic, enabling quicker cycle times and more precise part molding. Conversely, cold runner molds necessitate a runner for the molten plastic delivery but can yield parts with cleaner finishes and superior surface quality.

What maintenance is required for automotive battery terminal molds?

Consistent cleaning and appropriate storage are essential to extend the lifespan of automotive battery terminal molds and preserve their quality.

Can automotive battery terminal molds produce high-precision components?

Certainly, using molds with advanced shaping capabilities, such as compression moulding and die casting, available on Alibaba.com, it is feasible to manufacture high-precision parts.

What features are important in a high-voltage automotive battery terminal mold?

In high-voltage scenarios, it is crucial to select molds capable of withstanding elevated electrical demands and potential arcing from current interruptions during switching operations.

How do color variations in automotive battery terminal molds benefit production?

Different color options can serve branding purposes or functional needs. For example, red or black may be chosen for visual appeal, while blue or green could signify particular functional benefits.

Is Alibaba.com a source for all types of automotive battery terminal molds?

Alibaba.com hosts a network of suppliers offering a spectrum of automotive battery terminal molds, enabling businesses to find a comprehensive range of solutions on a single platform.