Popular in your industry

Related Searches:

Top categories

About aluminum alloy impeller

Exploring the Versatility of Aluminum Alloy Impellers

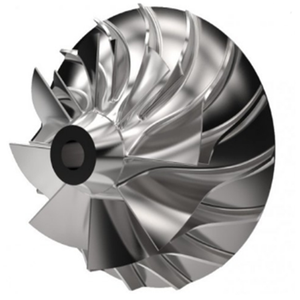

Aluminum alloy impellers are pivotal components in fluid movement technologies across various industries. Their primary function is to transfer energy from the motor to the fluid by accelerating the fluid outwards from the center of rotation. This category encompasses a broad range of designs, each tailored to specific applications and fluid dynamics.

Types and Applications of Aluminum Alloy Impellers

Diverse in application, aluminum alloy impellers cater to sectors ranging from pharmaceuticals to water sports. In the pharmaceutical industry, precision and contamination-free operations are paramount, and impellers designed for these environments ensure integrity in processes. Similarly, in the realm of perfume production, the delicate nature of the product demands impellers that can handle liquids gently to preserve quality. The food and beverage sector, including dairy and canning, also relies on these impellers for their non-corrosive properties and compliance with food safety standards.

For recreational and utility water transport, such as jet skis, jet impellers made from aluminum alloy provide efficient water propulsion. The material's resistance to corrosion and lightweight nature enhance the performance and longevity of these watercraft.

Design Features and Material Advantages

The design of an aluminum alloy impeller is a critical factor in its functionality. The impeller blades are meticulously connected to an adapter shaft, featuring a dedicated suction port for fluid intake. The structural integrity of aluminum alloy lends itself to creating impellers that are both lightweight and robust, offering a balance of efficiency and durability. The material's natural resistance to corrosion and wear extends the service life of the impellers, making them a cost-effective solution for fluid handling systems.

Axial flow impellers, a variant within this category, are engineered for applications requiring top-to-bottom circulation. They are adept at converting most of the motor's energy into fluid flow, making them suitable for processes that involve large volumes of liquid.

Selection Considerations for Aluminum Alloy Impellers

Choosing the right aluminum alloy impeller involves considering the power of the driving engine and the nature of the fluid to be pumped. For instance, pool impellers are designed to handle emulsions and can manage the small particulate matter often found in such environments. On the other hand, flexible impeller pumps offer adaptability, capable of operating under varying conditions and within different environments.

Materials used in the construction of impellers for pool cleaning are selected for their waterproof characteristics and wear resistance, ensuring efficient pool maintenance. The vast array of options available allows for a tailored approach to fluid handling, ensuring that specific operational requirements are met.

In conclusion, the aluminum alloy impeller is a testament to the innovation in fluid dynamics, offering a spectrum of solutions for efficient and effective liquid movement. While Alibaba.com serves as a marketplace to connect buyers with a multitude of suppliers, it is essential to engage with suppliers to ascertain the suitability of each impeller type for your application.