Popular in your industry

Top categories

About 5 axis cnc tool grinding machine

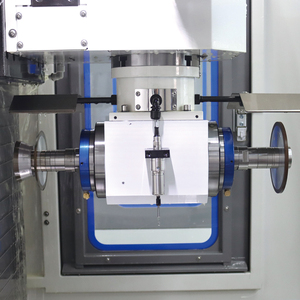

Introduction to 5 Axis CNC Tool Grinding Machines

The realm of precision manufacturing has been revolutionized by the advent of 5 axis CNC tool grinding machines. These sophisticated pieces of equipment enable the creation and maintenance of complex tools with high precision and efficiency. The term '5-axis' refers to the number of directions in which the cutting tool can move, allowing for intricate shaping and a high degree of versatility in operation.

Types and Applications

There are various types of 5 axis CNC tool and cutter grinders designed to meet diverse industry needs. From intricate aerospace components to detailed medical devices, these machines serve a broad spectrum of applications. Their adaptability makes them suitable for use in manufacturing plants, machinery repair shops, and even retail settings where precision tooling is essential.

Features and Materials

A 5 axis CNC grinding machine is equipped with advanced features such as a programmable logic controller (PLC), high-precision bearings, and robust motors. These features facilitate the machine's ability to handle various materials, ranging from metals to composites, with precision. The construction of these machines is a testament to engineering excellence, ensuring durability and consistent performance.

Advantages of 5 Axis Grinding Technology

The utilization of 5 axis grinding inc technology offers numerous advantages. It significantly reduces the time taken to produce complex tools and allows for the grinding of intricate shapes that would otherwise be impossible to achieve with conventional machinery. The enhanced capability of these machines also means that fewer setups are required, improving the overall efficiency of the grinding process.

Choosing the Right 5 Axis CNC Grinder

Selecting the appropriate 5 axis grinder involves considering the specific requirements of the task at hand. Factors such as the size of the tools to be ground, the level of precision required, and the type of material being worked on are crucial. Potential buyers should assess the specifications of each machine to ensure it aligns with their operational needs.

Global Availability

The global market for 5 axis CNC tool grinding machines is diverse, with options available from various regions including India, Thailand, and Peru. These machines are designed to meet international standards, ensuring they can be integrated into a wide range of industrial settings without compatibility issues.