Explore the Versatility of 4x8 Galvanized Mesh

The 4x8 galvanized mesh stands as a testament to versatility in numerous industrial and domestic applications. This mesh configuration is crafted to meet the demands of various projects, offering a blend of durability and functionality.

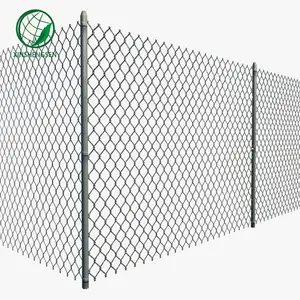

Types and Applications

From construction sites to home gardens, the galvanized wire mesh is utilized for its strength and resistance to corrosion. Its applications are diverse, including but not limited to, reinforcing concrete, crafting security panels, and creating custom fencing solutions. In agricultural settings, it serves as a robust framework for animal enclosures and protection against predators.

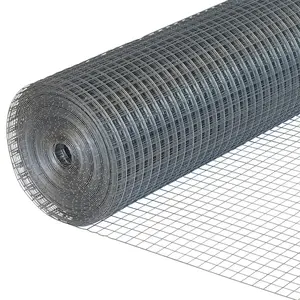

Features and Materials

The galvanized steel mesh is known for its protective zinc coating, which significantly extends its lifespan by guarding against rust. The mesh is composed of interwoven steel wires, ensuring a stable and uniform barrier. Its construction is designed to withstand environmental stressors, making it a reliable choice for outdoor and indoor use.

Advantages of Using 4x8 Galvanized Mesh

The primary advantage of galvanized mesh panels lies in their resilience. The hot-dip galvanization process provides a thick, defensive layer against moisture and mechanical damage. This mesh is also appreciated for its ease of installation and maintenance, offering a practical solution for a multitude of projects.

Customization and Adaptability

Wire mesh galvanized products are highly adaptable, capable of being cut and shaped to fit specific requirements. This adaptability makes them ideal for custom projects, ranging from intricate designs for decorative purposes to functional uses in sifters and screens.

Environmental Impact and Sustainability

The use of galvanized mesh also reflects a commitment to sustainability. The longevity of the material reduces the need for frequent replacements, thereby minimizing waste. Additionally, the galvanization process itself is continually refined to be more environmentally friendly, ensuring that the product's lifecycle remains responsible from production to application.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4