Laser Cutting Technology Overview

Laser cutting stands at the forefront of modern manufacturing and design, with the 400w CO2 laser cutter representing a versatile tool in this innovative field. This technology harnesses the power of a carbon dioxide mixed laser, offering a non-contact method of cutting a variety of materials with high precision.

Applications and Materials

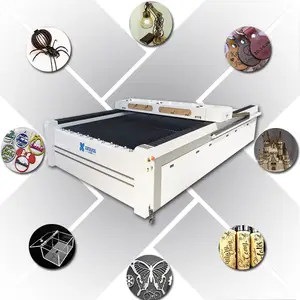

The CO2 laser engraving machine is not limited to a single industry or material, showcasing its adaptability across various applications. From intricate designs on fabric to detailed cuts on wood and acrylics, the laser cutting machine 400w is capable of handling diverse projects. Its use extends to the realms of metalworking, where it can shape carbon steel and stainless steel with the same ease and precision.

Features and Advantages

A 400w laser cutter is engineered for efficiency and precision. It minimizes material wastage and offers a clean cutting process, which is essential for both small-scale and large-scale production. The CO2 laser cutting machine stands out for its ease of use, requiring minimal setup with a compatible computer system for operation. This ease of integration into existing workflows makes it a valuable asset for businesses looking to enhance their production capabilities.

Choosing the Right Machine

Selecting a 400w CO2 laser involves considering the material compatibility and the intended use. For non-metallic materials like wood, fabric, plastic, and glass, a CO2 laser is ideal. For those working with metals, alternative laser types such as fiber lasers might be more appropriate. The key is to match the machine's specifications with the material's requirements to ensure optimal cutting results.

Design and Customization Capabilities

The laser cutter 400w is not just a cutting tool; it's also a designer's ally. It allows for intricate engravings and the creation of complex shapes, providing designers and fabricators with the ability to bring their visions to life with precision and ease. The versatility of the 400 watt laser cutter in handling various materials opens up a world of possibilities for customization and innovation.

Environmental and Operational Efficiency

In an era where sustainability is key, the 400w CO2 laser cutter offers an environmentally friendly option. The laser cutting process reduces contamination risks and conserves material by producing less waste. Furthermore, the operational efficiency of the CO2 laser cutter 400w means less energy consumption and faster production times, contributing to a more sustainable manufacturing process.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4