Popular in your industry

Top categories

About box furnace

Understanding Box Furnaces

A box furnace is an essential piece of equipment in the field of metalworking and materials science. These robust devices are pivotal for the melting and heat treatment of metals, offering a controlled heating environment for various industrial processes. The versatility of a box furnace lies in its ability to handle different metals, including iron, aluminum, copper, as well as precious metals like gold, silver, and platinum.

Types and Applications

The applications of box furnaces are diverse, ranging from small-scale jewelry manufacturing to large-scale industrial metal fabrication. They come in various sizes, with larger units capable of handling up to 20 tons of material. The working power of these furnaces can range from 180kw to a robust 2,000kw, tailored to meet the demands of different melting tasks. Their design often includes large capacitor banks to ensure current stability, crucial for the consistent operation of the furnace.

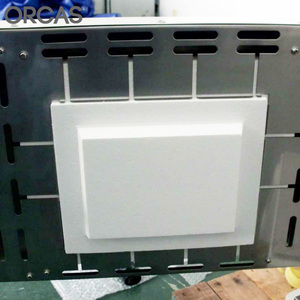

Features and Design

Safety and efficiency are at the forefront of box furnace design. Equipped with circuit breakers and insulated capacitors, these furnaces are designed to operate safely even in high-demand environments. The melting process can be conducted in either open or enclosed systems, with some models requiring dual pots for both melting and transportation of molten metal. Advanced models boast a PLC system for operational control and typically utilize electrical induction for heating. Hydraulic systems are often incorporated to facilitate the tilting of melting pots, which can pivot up to 95 degrees for effective material handling.

Performance and Advantages

In terms of performance, a box furnace is capable of reaching temperatures from 1,750 to 2,100 degrees Celsius, suitable for melting a vast range of metals. The melting speed is another highlight, with durations varying between 40 to 60 minutes depending on the metal and furnace specifications. Additionally, the inclusion of a water-cooling system aids in managing the temperature of the hot metal, enhancing the overall efficiency of the process.

Materials and Construction

The construction of a box furnace involves materials that can withstand extreme temperatures and provide durability. The melting pots, for instance, are designed to handle the intense heat and the physical demands of tilting and pouring molten metal. The structural integrity of these furnaces is paramount, ensuring longevity and consistent performance in industrial settings.

Choosing the Right Box Furnace

Selecting the appropriate box furnace for your needs involves considering the metal types you'll be working with, the required temperature range, and the volume of material to be processed. While Alibaba.com does not sell products directly, it serves as a marketplace to connect buyers with a wide array of suppliers offering various models of box furnaces. This platform allows for a comprehensive comparison of features and specifications to find a unit that aligns with your operational requirements.